Proven Products For Food and Beverage Manufacturing

Food and beverage (F&B) manufacturing is a massive global industry feeding billions of people throughout the world. In the US alone, over 42,000 F&B processing plants operate around the clock, powered by myriad machinery and equipment. And, with that many moving parts, things will break down resulting in costly downtime. Even small failures in minor parts like chains, switches and rotating equipment can wreak havoc on production lines and overall business operation.

Equipment failure and unexpected maintenance are the two leading causes of unplanned manufacturing downtime, and can have far-reaching negative effects, including:

- Overall financial impact

- Reduced employee safety and morale

- Compromised food safety

- Product damage and loss

- Regulatory compliance issues

- Supply chain and market disruptions

The Right Tools For The Job

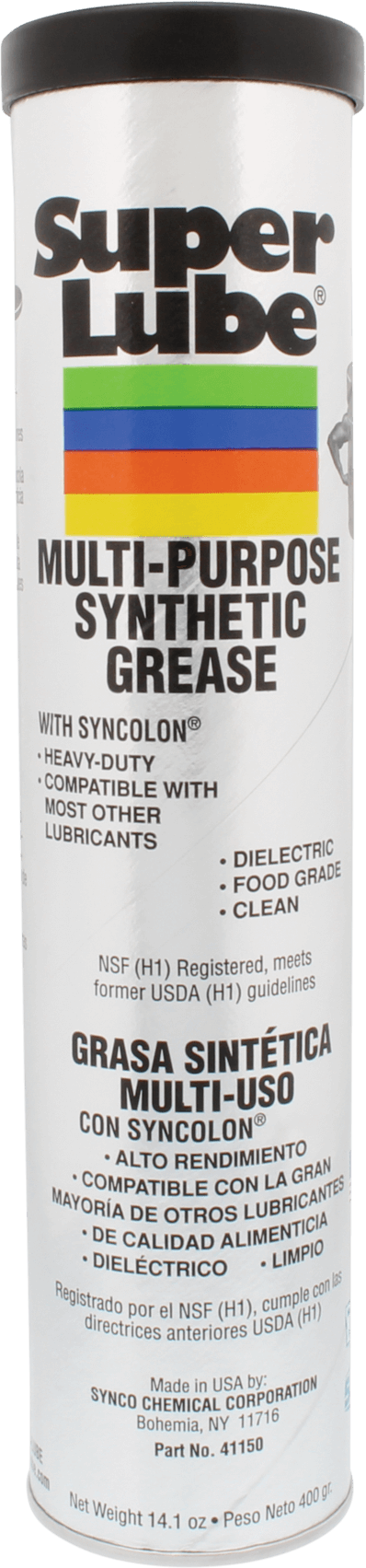

Food and beverage processing environments are highly corrosive due to extensive requirements for cleaning and sanitation, and the corrosive nature of many F&B products. When manufacturing equipment is not kept in good condition, it can become a breeding ground for microbiological and physical contamination that can impact production lines – or worse – enter the product directly. Maintenance technicians need to count on proven tools to perform their work quickly and effectively. That’s where Kano, the makers of Kroil and Super Lube®, comes in. Kroil Penetrants are NSF registered H2. Super-Lube products are NSF registered H1 or H3, and Kosher Certified. The pros regularly turn to the following products to save time, money and equipment:

Kroil Original Penetrant

When it comes to freeing corroded items in tough spaces, nothing rivals powerful, industry-proven Kroil penetrating oil. Kroil quickly loosens rusted nuts and bolts, frees frozen shafts, pulleys, conveyors and more. No space is too tight to reach, thanks to Kroil’s ability to penetrate the smallest opening, thread or crevice. Corrosion meets its match, as Kroil helps remove and prevent rust, cleans and lubricates, and displaces moisture. Kroil Penetrants are NSF registered H2, for parts and machinery that does not come into direct contact with food.

Silikroil, Kroil Penetrant with Silicone

Silikroil has been engineered to loosen frozen metal parts and provide extra lubrication for long-lasting protection. The addition of silicone to the legendary Kroil formula results in superior penetration, lubrication and rust prevention. This high solvency oil first penetrates into the tightest of spaces to break the bond of rust, and then provides lubrication at the first molecular level, subsequently freeing virtually any metal part. Kroil Penetrants are NSF registered H2, for parts and machinery that does not come into direct contact with food.

Penephite, Kroil Penetrant with Graphite

Penephite is a unique blend of oils, solvents and graphite engineered to penetrate the smallest gaps of corroded metals to loosen seized parts. The graphite is designed to stick to metal and provide long lasting lubrication, which will remain in place even in temperatures up to 700°F (371°C). Kroil Penetrants are NSF registered H2, for parts and machinery that does not come into direct contact with food.

What Customers Are Saying

Case Studies

Get the Right Products for Your Business